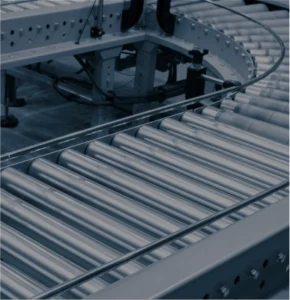

We use predictive models to assess product quality by analysing data from production processes, inspections, and customer feedback.

We identify patterns that correlate with defects or quality issues, allowing your business to take corrective actions early and maintain high-quality standards.

Mostly for Manufaturing clients, by tracking and analysing machinery performance over time, it is possible to generate descriptive models to understand typical causes for non-conformities.

Later on, we can build predictive models to forecast and notify systems when processes are out of tolerance or may yield quality concerns, anticipating the cause of non-conformities in the production line.

Being able to stop or adjust a process earlier can greatly reduce or eliminate material waste (scrap) or rework, and machine downtime.

BENEFITS

-

- Predict product quality during production based on the process parameters and find hidden root causes.

- Optimise process parameters for less scrap and higher quality.

- Reduce inspection costs and call-back risks.

- Reduce waste, and therefore increase sustainability of the production process.

We mostly use Quality Analytics in the following industries: