Our predictive models help businesses forecast demand for products or services. By analysing historical sales data, seasonality, economic factors, and external events we can optimise inventory levels, allocate resources efficiently, and minimise overstock or stockouts.

We also use predictive models to do cost forecasting to predict future expenses based on historical spending patterns, market trends, and other relevant factors. It enables better budget planning and cost control for your company.

Internal DB, ERP, unstructured data like emails (anonymised), open data (e.g. weather, exchange rates), internet data (news, transport disruptions, etc) can be relevant to predictive models to extract hidden patterns that generate meaningful cost and demand variations over time.

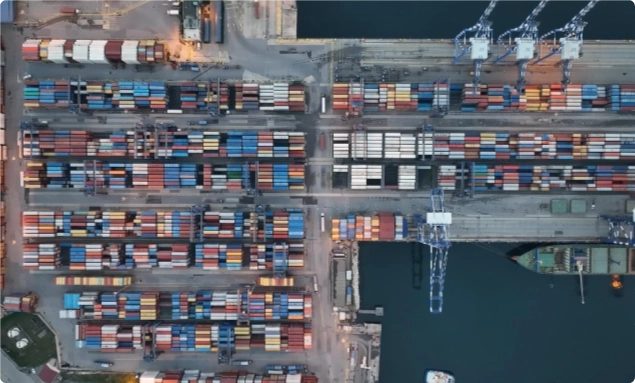

Especially in markets where material prices may greatly be affected by politics, natural disasters, etc., using data to predict consumption rates and shipping can offer great benefits in streamlining supply chain management.

Predicting volume, timelines, cost and market demand will help manage economics and cost for new equipment, products, and optimise internal processes.

Demand forecasting relies heavily on historical data on supply levels, material costs, purchasing trends, consumer buying habits, and delivery conditions.

Benefits

-

- Calculate the number of products to manufacture.

- Forecast possible sales and deliveries.

- Determine out-of-stock items.

- Identify trendy products in each period.

- Allocate resources.

- Plan budgets.

We mostly use Predictive Models in the following case studies: