Mosaic Factor’s higher priority in Manufacturing is aid our clients decrease costs, increase sustainability while streamlining the production chain.

TYPICAL USE CASES WE TACKLE FOR MANUFACTURING ARE:

PREDICTIVE MAINTENANCE

use historical and real-time data to anticipate equipment failures or maintenance needs.

assess product quality with data from production processes, inspections, and customer feedback.

Quality Analytics

Cost and demand forecasting

predict volume, timelines, cost and market demand to manage economics and optimise internal processes.

Consider factors such as lead time, demand variability, and storage costs.

Inventory Management

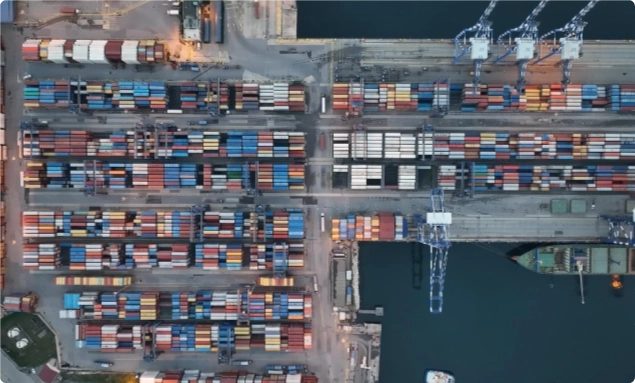

Supply chain management

analyse historical data, weather patterns, transportation delays, and supplier performance to improve sourcing, logistics, and distribution

explainable AI solutions to visualise how the algorithms work and provide transparency and safety in the use of AI models.

TRUSTWORTHY AI